RedBarron55

Jet Boat Addict

- Messages

- 280

- Reaction score

- 100

- Points

- 122

- Location

- Navarre, FL

- Boat Make

- Jetcraft

- Year

- 1995

- Boat Model

- Other

- Boat Length

- 16

OK I replaced the exhaust manifold gasket and head gaskets and put the boat in the water and ran it.

It did't want to start and idle with the carbs set closed so that the enrichment valve would work, but a spritz of ether started it up.

Let it warm up and to start it didn't want to take throttle, but with a little coaxing I could get it to run to 4000 rpm. It wanted to die at about 3000 and I changed to a portable tank instead of the built in tank with the new water separator filter. (perhaps the fuel pump is a little weak).

Two observations

1. I left the boat on the trailer and the jet stayed under water and is 4000 rpm OK with this configuration> I mean would the fact that the jet outlet is submerged and not up in the air on a plane load the engine so that 4000 is reasonable?

2. When I took the boat home to flush it and with the hose set to a very low flow there was a trickle of water from the ride plate area. Being cautious i tried turning the flywheel by hand and it was locked up when it came to #3 again.

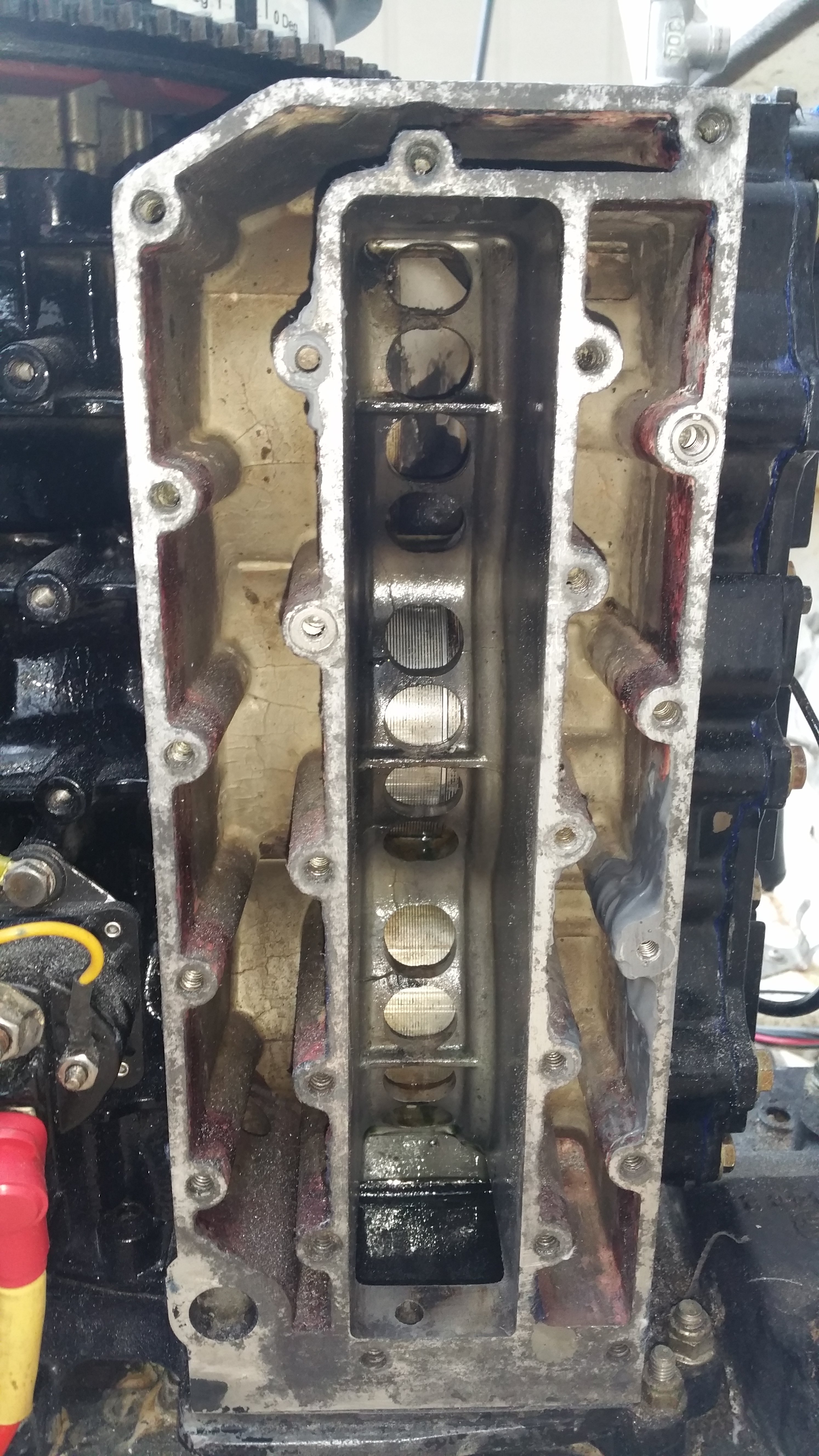

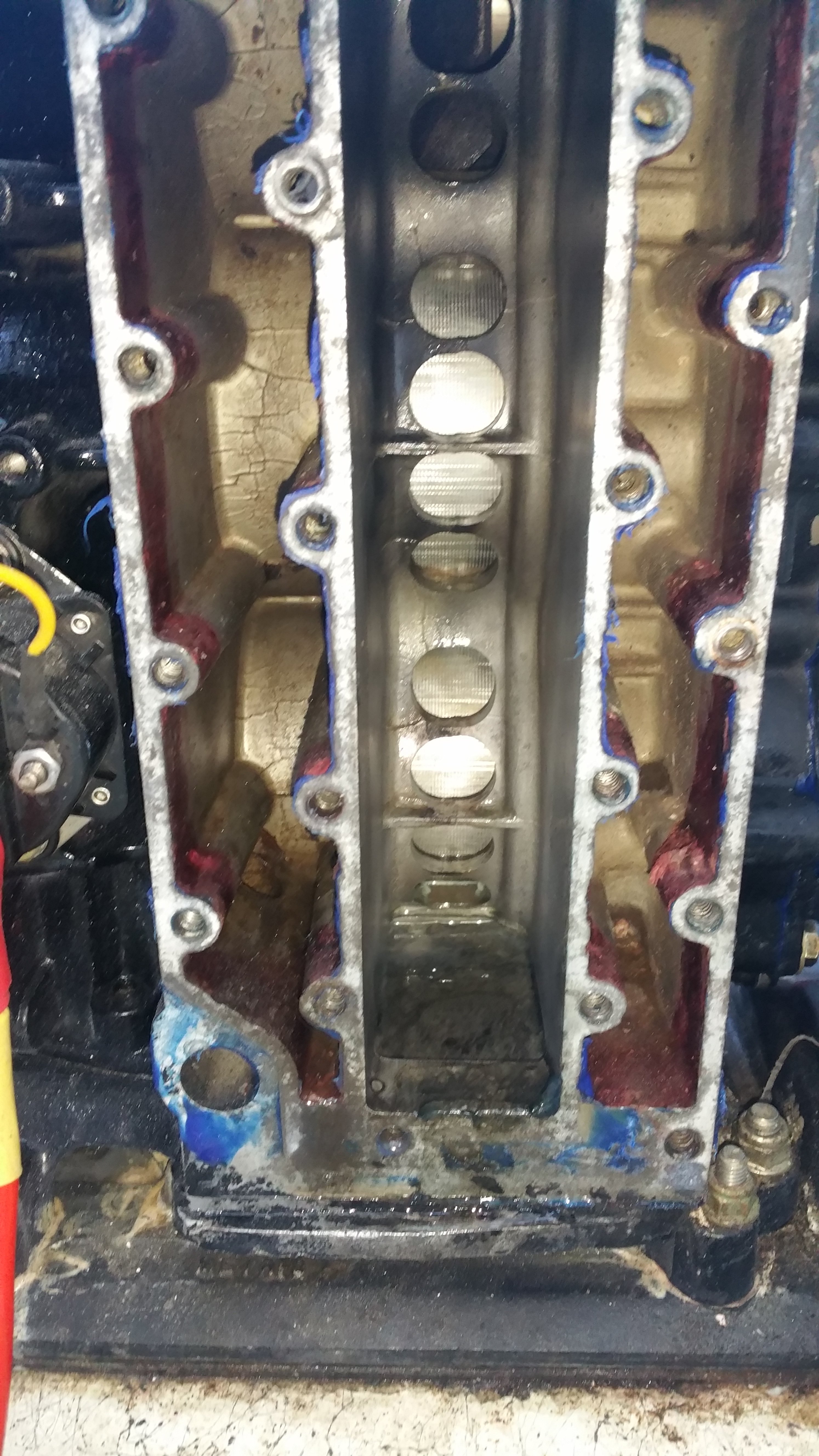

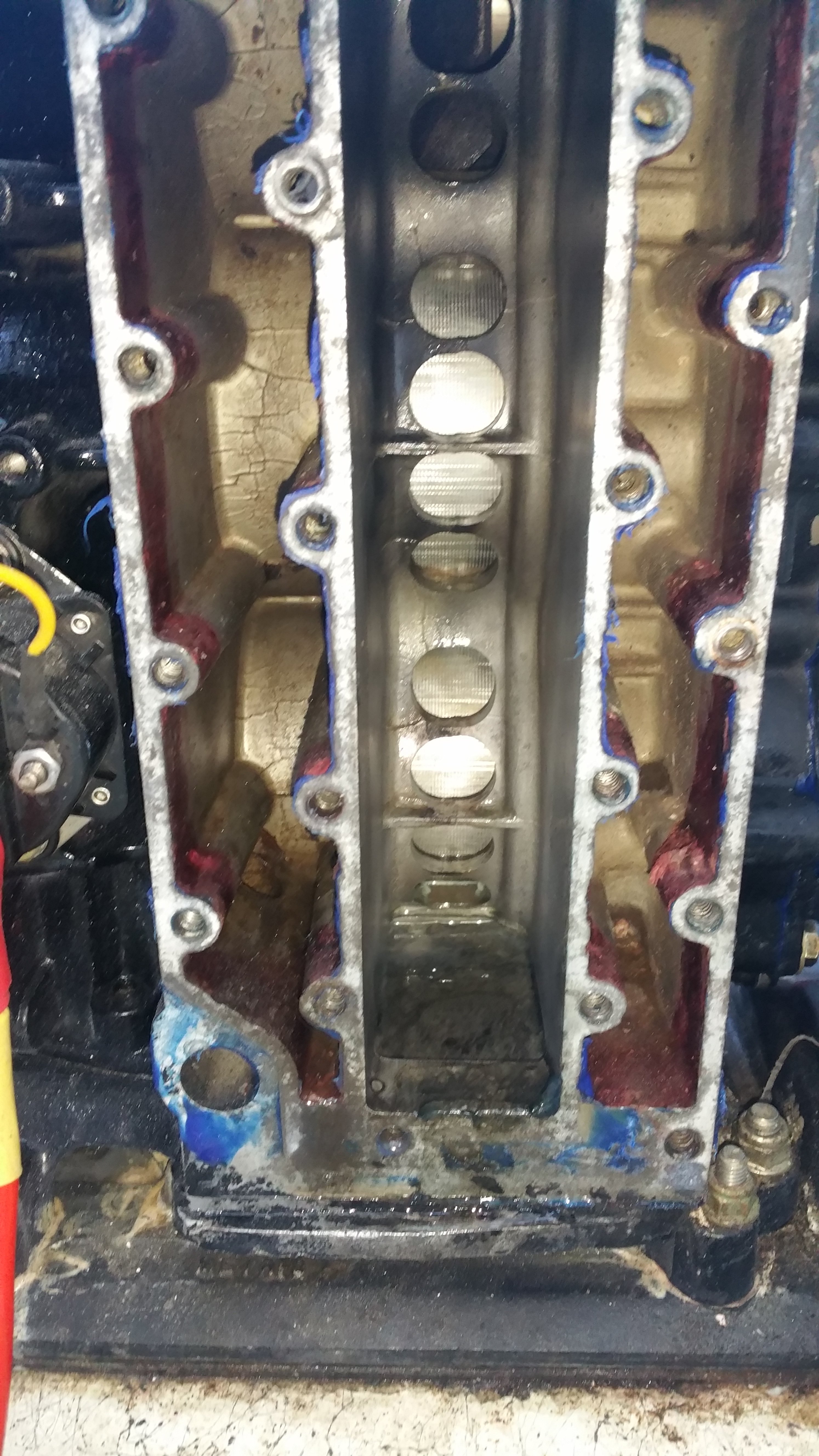

Removed plug and out comes water again!!! water more or less straight from the exhaust manifold to the lower cylinder!

I pulled the exhaust manifold and the helicoils that were ground down flush are pulled out again.

So I am completely removing the coils and either tapping the holes deeper and using longer bolts or installing Time-Serts if they will fit with the helicoil insert pulled out and messed up.

It seems that most if not all of the helicoil or whatever repairs installed are giving trouble or could expect to in the future.

Two of the three I see with a cursory examination are repeats that were ground down leading me to expect more trouble unless completely replaced.

Perhaps as I have seen on one of the forums the suggestion was to drill and tap deeper since there is plenty of distance before you get into the cylinder area. Since a coarse thread in aluminum develops full strength with 2 X diameter of the bolt since these are 1/4 - 20 the depth should be 1/2", but let's go for 3/4 - 1" with longer bolts.

I am going to see if I can extract the repairs later today when it warms up a little and see how much material is left to work with. If there is enough for a Time-Sert I may use them since they actually swage into place to hold them in and they are also available in stainless.

Does anyone have any suggestions?

I think that this is the remaining problem.

Thanks,

It did't want to start and idle with the carbs set closed so that the enrichment valve would work, but a spritz of ether started it up.

Let it warm up and to start it didn't want to take throttle, but with a little coaxing I could get it to run to 4000 rpm. It wanted to die at about 3000 and I changed to a portable tank instead of the built in tank with the new water separator filter. (perhaps the fuel pump is a little weak).

Two observations

1. I left the boat on the trailer and the jet stayed under water and is 4000 rpm OK with this configuration> I mean would the fact that the jet outlet is submerged and not up in the air on a plane load the engine so that 4000 is reasonable?

2. When I took the boat home to flush it and with the hose set to a very low flow there was a trickle of water from the ride plate area. Being cautious i tried turning the flywheel by hand and it was locked up when it came to #3 again.

Removed plug and out comes water again!!! water more or less straight from the exhaust manifold to the lower cylinder!

I pulled the exhaust manifold and the helicoils that were ground down flush are pulled out again.

So I am completely removing the coils and either tapping the holes deeper and using longer bolts or installing Time-Serts if they will fit with the helicoil insert pulled out and messed up.

It seems that most if not all of the helicoil or whatever repairs installed are giving trouble or could expect to in the future.

Two of the three I see with a cursory examination are repeats that were ground down leading me to expect more trouble unless completely replaced.

Perhaps as I have seen on one of the forums the suggestion was to drill and tap deeper since there is plenty of distance before you get into the cylinder area. Since a coarse thread in aluminum develops full strength with 2 X diameter of the bolt since these are 1/4 - 20 the depth should be 1/2", but let's go for 3/4 - 1" with longer bolts.

I am going to see if I can extract the repairs later today when it warms up a little and see how much material is left to work with. If there is enough for a Time-Sert I may use them since they actually swage into place to hold them in and they are also available in stainless.

Does anyone have any suggestions?

I think that this is the remaining problem.

Thanks,

Last edited: