Speedling

Jetboaters Admiral

- Messages

- 5,278

- Reaction score

- 4,543

- Points

- 442

- Location

- Cedar Lake, IN

- Boat Make

- Yamaha

- Year

- 2008

- Boat Model

- SS

- Boat Length

- 21

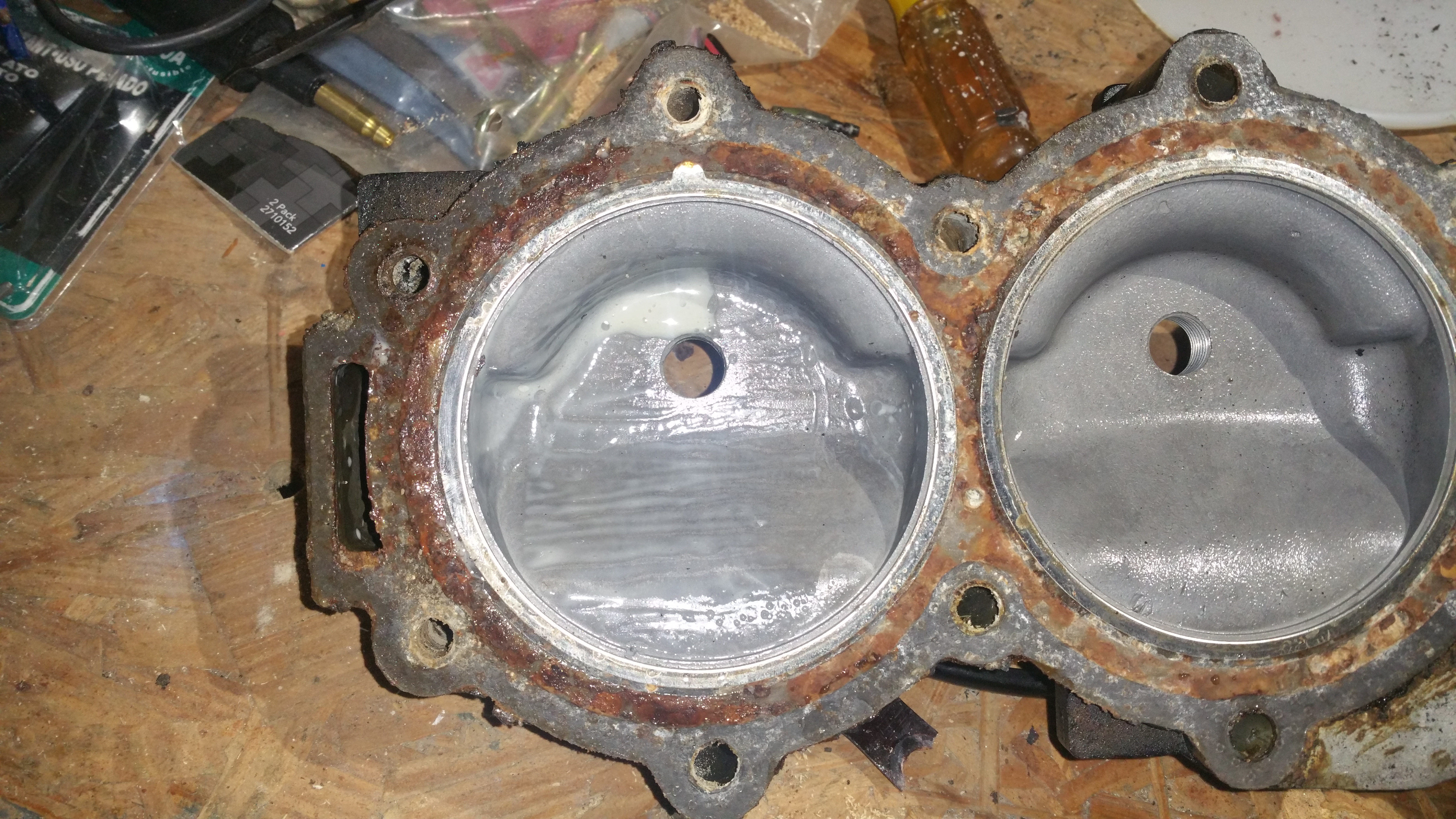

If the gasket is a burnable material you could be right!

I wonder if a gasket could be made of like copper or something? Copper may be a poor choice but trying to think of something metal but softer than aluminum

I wonder if a gasket could be made of like copper or something? Copper may be a poor choice but trying to think of something metal but softer than aluminum