@MilesPrower you didn't use any washers or anything under the barrel nuts on the outside to spread the load? They aren't really any bigger than the bolts I was looking at, I'm worried about cracking the fiberglass with years of bouncing around.

Thanks!

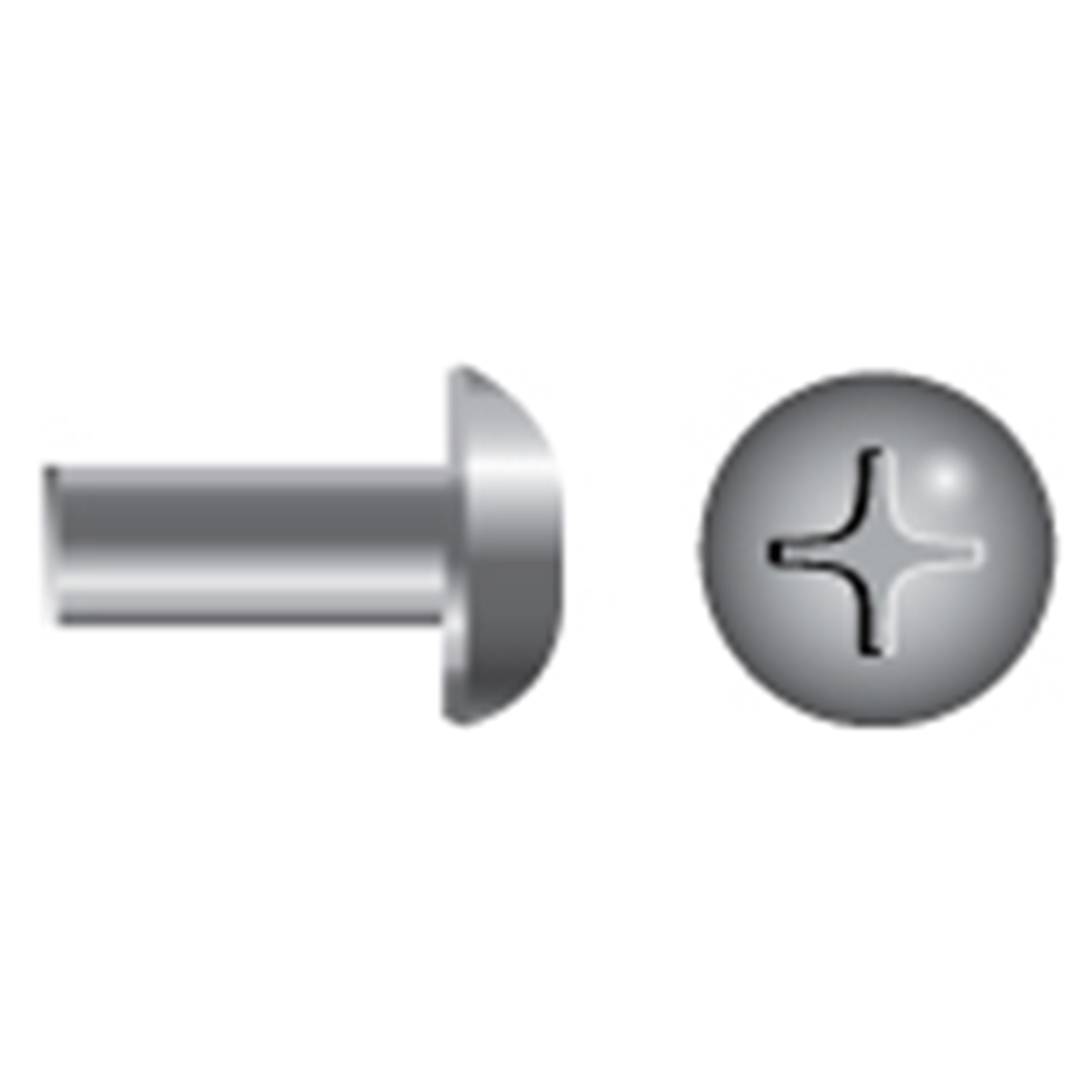

Sorry for not being clear. Yes, I am using washers under the barrel bolts, but they're not wide-diameter fender washers. I'm using washers that are the same size as the barrel nuts' heads. And yes, I would highly recommend using washers, because the barrel nuts have ridges on the mating surface of their heads to prevent spinning.

Also, the barrel nuts are significantly bigger than the corresponding bolts, because the bolt has to thread

into the barrel nut. When you place the barrel nut next to the bolt, you can see how much bigger the head of the barrel nut is. Therefore, the head of the barrel nut offers more surface area without having to rely on a bigger fender washer.

Moreover, I am "spreading the load" a bit further by using 6 barrel nuts per Halotron extinguisher (9.5 lb weight with a stainless USCG compliant bracket).

I haven't experienced any cracking at the barrel-nut side of the gelcoat on any of my boats... even though I pound through 1-3 ft seas to get 10-20 miles offshore at least a couple times a month, and sometimes spend hours trolling at 7+ knots in those seas.

When I drill holes through gelcoat, I tape up the gelcoat before I drill the hole (as we all do, right?). After I remove the tape, I use a 90° cross-hole (AKA zero-flute) countersink bit (vs. a standard 82° fluted bit) to remove a slightly wider diameter of the gelcoat layer than the widest point of whatever section of the fastener is going into the hole. A cross-hole countersink will also deburr the gelcoat-fiberglass interface, further reducing the chances of the gelcoat cracking when you insert and tighten a fastener.

Also, make sure you install the washers so that the rounded edge is toward the gelcoat. Stainless-steel washers are manufactured by stamping them out of a sheet of steel. Therefore, one side of the washer will have smooth, rounded edges, while the other side will have sharp edges. Make sure the rounded side touches the gelcoat.

If you're still really concerned of cracking the gelcoat, I'd recommend going with white nylon washers under the barrel nuts so that the washer will offer a softer material against the gelcoat, in case there's an uneven load due to slight angling of the fastener.

And don't forget to use Loctite or equivalent on the threads of the barrel nuts. (I prefer nail polish over Loctite.)