Mainah

Jetboaters Admiral

- Messages

- 3,016

- Reaction score

- 4,052

- Points

- 362

- Location

- Chapin, SC

- Boat Make

- Yamaha

- Year

- 2016

- Boat Model

- Limited S

- Boat Length

- 24

Edit - This is now done and installed in the boat. More details below.

I started with a top loading water cooler and first turned it into this ....

Then I turned it into this ...

Original post here with new details and photos below - Not in the boat yet but it works. Still need to work out a sheild for the compressor because that thing gets hot and a cover for the beverage coller to keep the collant in (water right now to tranfer the coil temp to the keg). In about an hour at 80 degrees in my garge and a starting temp of 55 degrees for the beer and collant I had 1 gallon of COLD beer and the keg was frozen into the cooler. May need to use rv anti freeze for the collant and adjust the thermostat. Will look less like a mad science project and more like a finished product once in the boat. This has been my favorite project to test I will update once I get it in the boat so if intrested stay tuned.

I will update once I get it in the boat so if intrested stay tuned.

First the updated photos ...

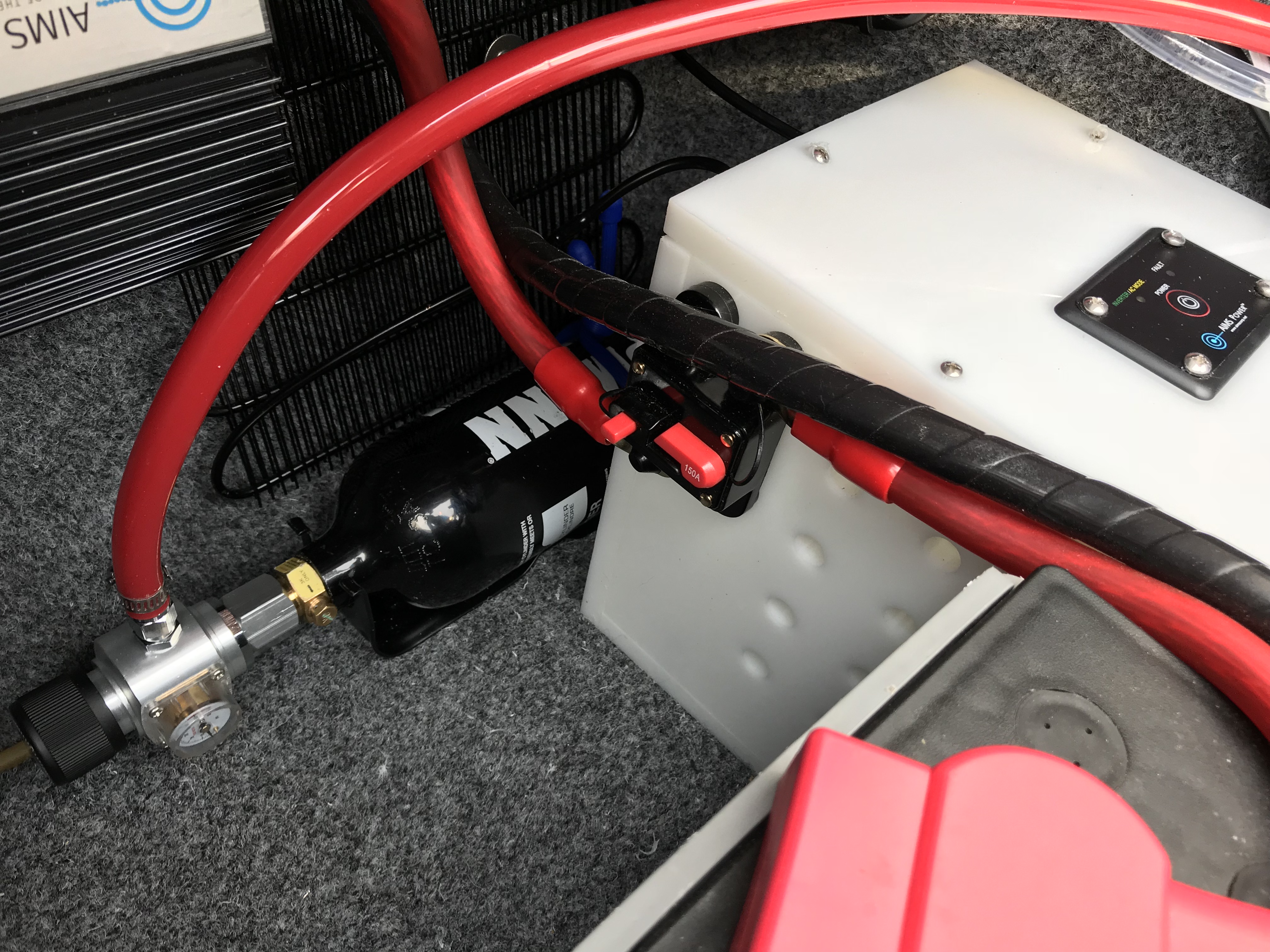

I started by building a vented case out of HDPE for the compressor. I installed a stabilizing ring in the sport cooler vessel about half way down and spray foamed the top end for better insulation and keg support which also ensure the cooling water stays at the bottom with the cooling coil to conduct the thermal energy to the 1 gallon stainless keg. I had to fiberglass in mounting boards into the hull for the pure sine wave inverter with auto switch over when connected to shore power and the compressor radiator. I used a fire extinguisher mount for the 24 oz paintball co2 tank with is good for dispensing about 36 gallons of beer and keeping it carbonated. I have a pump cleaning system for the beer line to keep it from getting nasty with stale beer sitting in it with the heat. Unfortunately the speaker had already been mounted so I had to angle the tap over the cupholder which now doubles as a drip tray that tees into other drain lines in the bilge exiting the hull and has a 1 way ballast valve install for all the drain lines. I have a second pressurized keg on standby as well.

At the end of the day I spent an immense amount of time and effort solving a problem that really did not need solved but this is very fitting for a boat that I had already named Liquid Therapy.

I started with a top loading water cooler and first turned it into this ....

Then I turned it into this ...

Original post here with new details and photos below - Not in the boat yet but it works. Still need to work out a sheild for the compressor because that thing gets hot and a cover for the beverage coller to keep the collant in (water right now to tranfer the coil temp to the keg). In about an hour at 80 degrees in my garge and a starting temp of 55 degrees for the beer and collant I had 1 gallon of COLD beer and the keg was frozen into the cooler. May need to use rv anti freeze for the collant and adjust the thermostat. Will look less like a mad science project and more like a finished product once in the boat. This has been my favorite project to test

First the updated photos ...

I started by building a vented case out of HDPE for the compressor. I installed a stabilizing ring in the sport cooler vessel about half way down and spray foamed the top end for better insulation and keg support which also ensure the cooling water stays at the bottom with the cooling coil to conduct the thermal energy to the 1 gallon stainless keg. I had to fiberglass in mounting boards into the hull for the pure sine wave inverter with auto switch over when connected to shore power and the compressor radiator. I used a fire extinguisher mount for the 24 oz paintball co2 tank with is good for dispensing about 36 gallons of beer and keeping it carbonated. I have a pump cleaning system for the beer line to keep it from getting nasty with stale beer sitting in it with the heat. Unfortunately the speaker had already been mounted so I had to angle the tap over the cupholder which now doubles as a drip tray that tees into other drain lines in the bilge exiting the hull and has a 1 way ballast valve install for all the drain lines. I have a second pressurized keg on standby as well.

At the end of the day I spent an immense amount of time and effort solving a problem that really did not need solved but this is very fitting for a boat that I had already named Liquid Therapy.

Last edited: