danclemo

Jet Boat Lover

- Messages

- 99

- Reaction score

- 81

- Points

- 77

- Boat Make

- Yamaha

- Year

- 2017

- Boat Model

- AR

- Boat Length

- 19

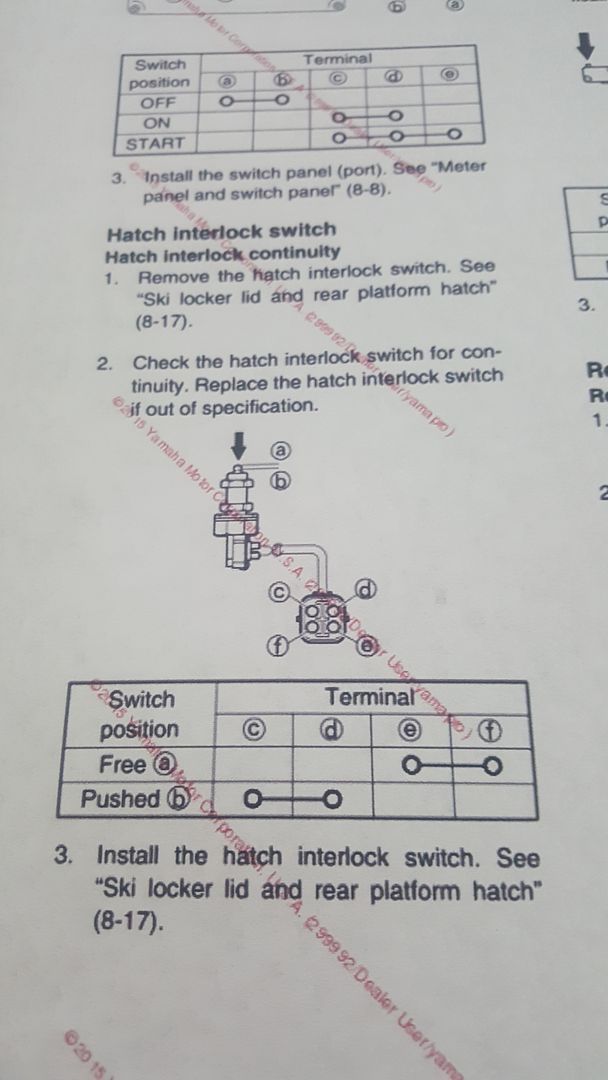

With all the Clean-out hatch switch issues I see on here I can't seem to find a thread about jumpering around this stupid thing? I had my out today and there are two wires in (both brown) and two going out (White/Black). Does anyone know the circuit for this, I would like to just hard wire around this and remove this switch. I was hoping it was just one and one out and it would have been no-brainer.

And no, this is not a debate on rather I should jumper this or not....I realize it's a safety issue and I shouldn't, but I'm going too...LOL

Any help appreciated. Thanks.

And no, this is not a debate on rather I should jumper this or not....I realize it's a safety issue and I shouldn't, but I'm going too...LOL

Any help appreciated. Thanks.