Cambo

Jetboaters Admiral

- Messages

- 1,499

- Reaction score

- 1,066

- Points

- 257

- Location

- Long Island

- Boat Make

- Yamaha

- Year

- 2017

- Boat Model

- 242X E-Series

- Boat Length

- 24

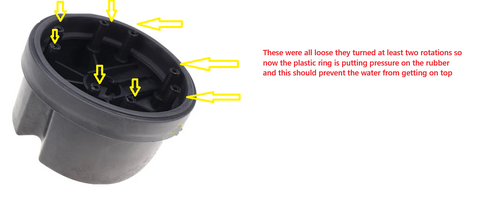

Has anyone else taken apart the clean out plug and noticed how loose the six screws are on the plastic ring that holds down the rubber part of the clean out ? This O ring would make perfect sense because if the screws are loose it would put more upward pressure on the rubber part to seal it better. I did install the o rings and put some Zero pool and spa o ring lubricant now that they should be bone dry it wont wash the lube off. Beginning of every season I would take a scotch brite pad and reach in the man hole and scrub the aluminum notches that the plug twists into this would knock down any oxidation build up and allow them to rotate with minimal friction. Now even with the o ring its very easy to remove and install.