- Messages

- 18,702

- Reaction score

- 21,162

- Points

- 1,102

- Location

- Raleigh, NC 27614

- Boat Make

- Yamaha

- Year

- 2016

- Boat Model

- 242X E-Series

- Boat Length

- 24

Great thread with fantastic pics and steps....added this to the FAQ under maintenance #5!

We are delighted you have found your way to the best Jet Boaters Forum on the internet! Please consider Signing Up so that you can enjoy all the features and offers on the forum. We have members with boats from all the major manufacturers including Yamaha, Seadoo, Scarab and Chaparral. We don't email you SPAM, and the site is totally non-commercial. So what's to lose? IT IS FREE!

Membership allows you to ask questions (no matter how mundane), meet up with other jet boaters, see full images (not just thumbnails), browse the member map and qualifies you for members only discounts offered by vendors who run specials for our members only! (It also gets rid of this banner!)

Holy crap Ken @Big Shasta, welcome! Sorry about the trouble's but certainly glad it didn't happen to you sooner on your vacation. A few years back I replaced the grease in the cones of my old 230 while changing my impellers out and I used the stuff from Island Racing - as noted by Bruce above. I highly recommend it! I'd be more than happy to send you the one I have, I bet it would fit. Send me your address I'll mail it tomorrow.

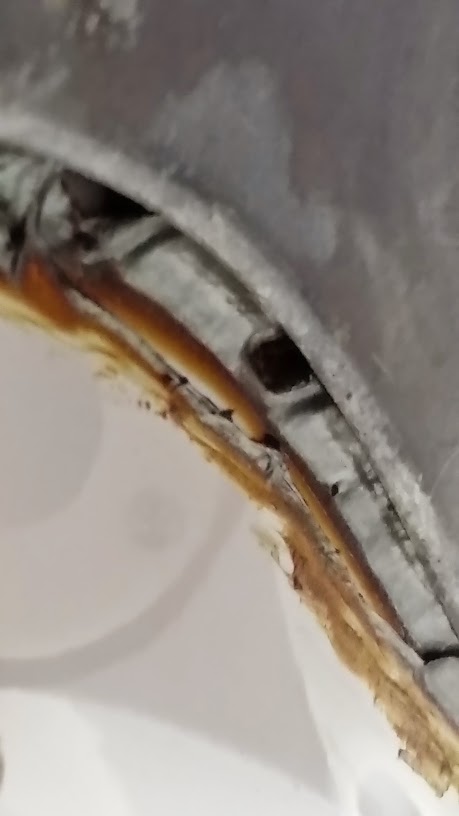

View attachment 9043

Holy crap Ken @Big Shasta, welcome! Sorry about the trouble's but certainly glad it didn't happen to you sooner on your vacation. A few years back I replaced the grease in the cones of my old 230 while changing my impellers out and I used the stuff from Island Racing - as noted by Bruce above. I highly recommend it! I'd be more than happy to send you the one I have, I bet it would fit. Send me your address I'll mail it tomorrow.

View attachment 9043

Not to worry @Big Shasta. We'll just talk your wife through the repair. It'll be ready for ya when you return.THANKS @Rigger . Finally got home from my 1st trip, got the impeller tool. Can't thank you enough. Got a good night sleep and a welcome back from the wife....time to hit the road again, flight leaves at 11 am. It's going to kill me knowing these parts are all sitting here waiting until I get back on Friday. Saturday he gets the goods installed!

Awesome...The box of parts are in the garage, beer fridge has lots of choices and I have every tool you can imagine! But you better do it while she just watches if it's gonna work right....she's not much for tools.Not to worry @Big Shasta. We'll just talk your wife through the repair. It'll be ready for ya when you return.