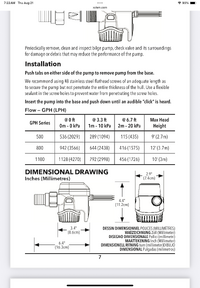

I would recommend NOT installing a larger pump in the OEM bilge pump chassis and feeding it with the OEM wiring via a larger fuse.

You can’t just put in a larger capacity pump and fuse into the OEM WIRING without checking that the conductor size is adequate for the increased load. I’m not familiar with exactly how your system is wired, if the current flows through the connext system / screen itself, it may not be designed to handle the extra load, that would be…..expensive to say the least.

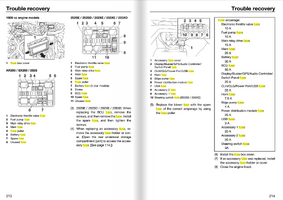

The fuse for the device is at the origin of the conductor run to the device and protects the conductor and the pump.

In addition to the number of vanes in the pump, the 800 gph pumps’ ability to move more water requires a motor that has more windings in it to produce more power, more power produced by the pump increases the amount of current being drawn from the battery via the fuse link (skinny rope) and the conductor.

The reason the icon changes on the connext screen is the same reason the back lit rocker switch lights up, the light is wired in series with the pumps motor, once the pumps float switch closes and completes the circuit current flows through the light causing it to illuminate and the pumps motor to run. In the connext screen the status of the circuit changes state and that causes the change in the icon.

If your bilge pump is the same style as the one in my boat then there are two fuses that feed the bilge pump, one for the auto functionality, this fuse is usually near the batteries, and the other fuse or in my case a circuit breaker, that feeds the manual switch.

Install a stand alone secondary bilge pump.

I don’t know if your boat came with extra switches for accessories or not, mine did, those switches for a fish finder / chart plotter etc and the other OEM switches, live well fill, aerator, bilge pump etc are all fed from the main accessory fuse, and so is the manual side of the OEM bilge pump. I wanted my second bilge pump to run independently of the OEM wiring in case something happened I’d have a bilge pump that would run on its own. So I installed an auxiliary 12V bus with a separate 10GA wire feed from its own 30A circuit breaker fed from the battery, then fed my second bilge pump off of that system with its own 5A circuit breakers, one for the auto side and another for the manual side.

You could do something similar and simpler, just run a feed from the battery for the new secondary bilge pump off of the battery, one for the auto side and one for the manual side and put a switch on the dash. If your boat came with the aforementioned accessory switches you could run this separate feed directly to one of those switches and just remove the OEM wires from the switch and safe them.

I prefer circuit breakers over fuses